ReVentas are in the process of scaling their new technology up to the pilot scale, having completed the designs in 2021/2022 and started construction. Results so far have proven the commercial feasibility of the process and shown the end product is of high quality and desired by end users, with further trials being undertaken in the 2nd half of the pilot project. The pilot plant will allow the validation of the technology by end users. ReVentas are in the process of identifying and building partnerships with key strategic partners for the future scale-up and commercial expansion of the technology.

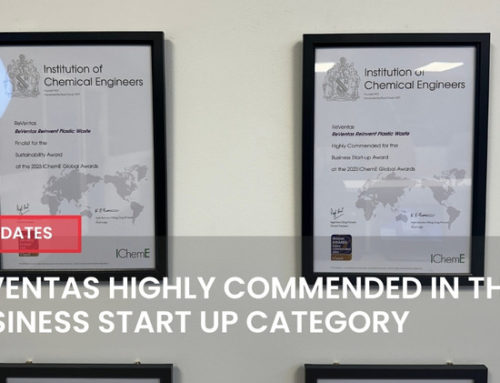

ReVentas’s current programme focuses on developing the process to selectively decontaminate and “tune” the end properties of recycled Polyethylene, one of the most common plastics used in packing. By adjusting the physical properties and returning the material to a natural state, ReVentas will be able to develop polymers adjusted to the customers’ needs (blow moulding, injection moulding, film) and remove the variability inherent in waste plastic feedstocks. Ultimately this will greatly increase the use of recycled polymer in packaging applications by giving manufacturers the performance and reliability they need whilst also opening up new feedstock for ReVentas to tackle.

![flag_yellow_eps-2-[Converted] EU Horizon 2020](https://reventas.co.uk/wp-content/uploads/2022/05/flag_yellow_eps-2-Converted-e1652277552988.jpg)

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 101010875